Crusher Parts

Jaw Plate

Description: The plates mounted on jaw crushers, in which one plate oscillates and other stands stationary are called jaw plates. The oscillating movement narrowing the valley of the crushing chamber makes the crushing media squeezed between the Moving and fixed Jaw Plate and makes the reduction in the size of the stones possible.

Application: In a jaw crusher the crushing takes place by squeezing the material between stationary and moving jaw plates. The Jaw plate thus plays a lead role in a jaw crushing machine. The peaks and valleys of the jaw plates are offset from one another and use the mechanical advantage of leverage to break the rock. The jaw plates are casted in different grades of Mn steel to suit the crushing media and different weather conditions. The crushing media is crushed between the movement of the stationery and movable jaw plate resulting in the smaller size than original.

Our Competency: Jaw plate casted by us can in all desired Mn steel grades following either IS/ASTM or Customer proprietary standard, give you the best of the possible output and easy replaceability. It is casted with utmost care at every process to provide you the desired performance

Bowl Liner

Description: The Bowl Liner ring is the stationary crushing surface of a cone crusher casted in Mn steel. The concave works as the outer layer of the crushing chamber, in which the crushing of the aggregates is taking place.

Application: The Bowl Liner acts as an outside wall of the crushing area in the cone crusher which remains stationary and fixed in the cone crusher frame. The Angular inside wall of the Bowl Liner allows the crushing material to squeeze between the moving Mantle and the Bowl Liner, resulting in the reduction in the size of the crushing media as the crushing media breaks into small pieces.

Our Competency: Bowl liner supplied by us is produced with utmost precision in every process of castings manufacturing to provide the desired output at the installed site.

Concave

Description: The concave ring is the stationary crushing surface of a cone crusher casted in Mn steel. The concave works as the outer layer of the crushing chamber, in which the crushing of the aggregates is taking place.

Application: The concave acts as an outside wall of the crushing area in the cone crusher which remains stationary and fixed in the cone crusher frame. The curved inside wall of the concave allows the crushing material to squeeze between the moving Mantle and the concave, resulting in the reduction in the size of the crushing media as the crushing media breakes into small pieces.

Our Competency: Concave supplied by us are produced with utmost precision in every process of castings manufacturing to provide the desired output at the installed site.

Mantle

Description: The mantle is a movable part of the cone crusher casted in different grades of Mn Steel.

Application: The mantle acts as the inside wall of the crushing area and its movement pushes the crushing media to break into the smaller pieces.

Our Competency: Mantles supplied by us are thoroughly QC checked to provide a hassle free replaceability at the installation site.

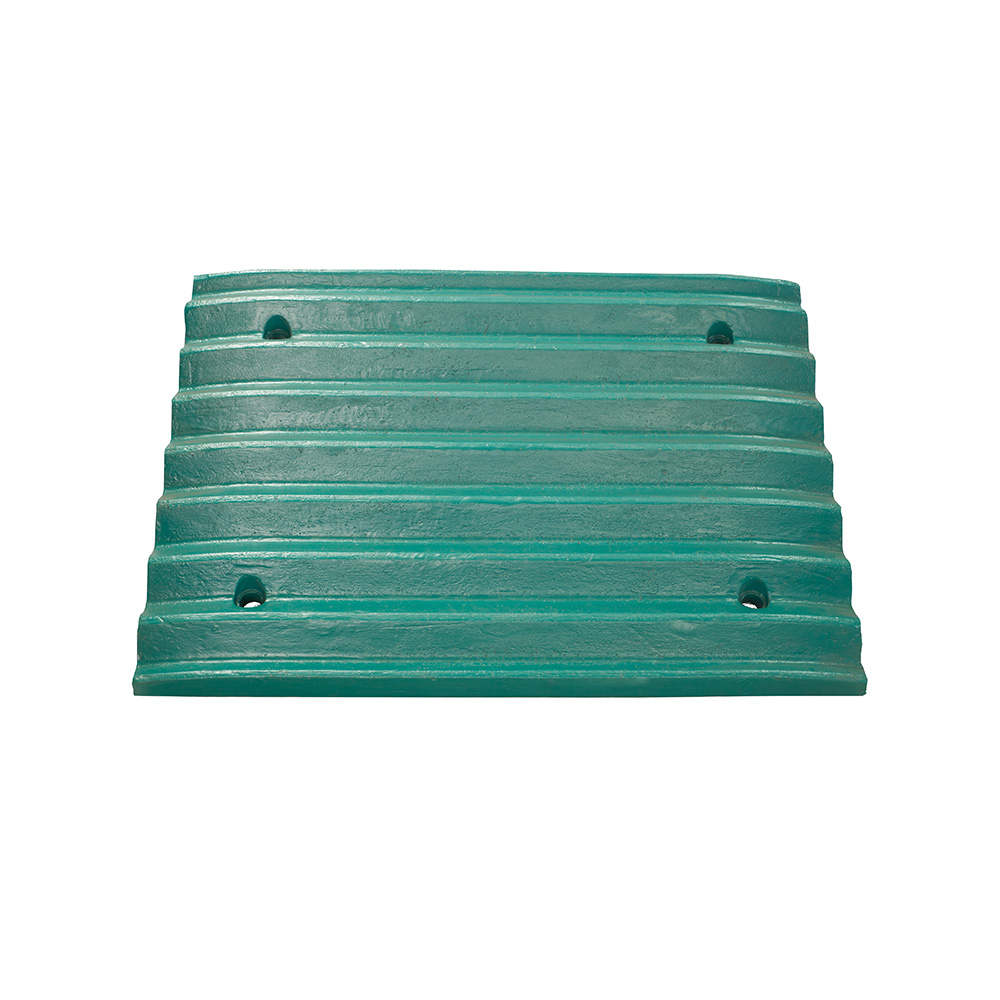

Cheek Plate/Side Plate / Side Liner

Description: A Cheek Plate/Side Plate / Side Liner, though being a comparatively small part of the crusher, is a very important element of the machine. The Plate/Side Plate / Side Liner acts as a side wall of the crushing chamber casted in Mn steel grades.

Application: The Cheek Plate/Side Plate / Side Liner is installed on both side of the Jaw Plate assembly in the crushing chamber. Cheek Plate/Side Plate / Side Liner works as a was protective barrier between the crushing machine body and the crushing chamber. Cheek Plate/Side Plate / Side Liner does not allow the crushing media to fall out of the crushing chamber and helps the material to remain the crushing chamber.

Our Competency: The Cheek Plate/Side Plate / Side Liner castings provided by us casted in the desired chemical composition with utmost care for following your every requirement. We have established process monitoring system to ensure the best possible quality of the product we manufacture.